Call: or Contact Us

- Home

- About Us

-

Products

- Pre-treatment Chemicals

-

Electroplating Intermediates

- Acid Copper Plating Intermediates

- Acid Zinc Plating Intermediates

- Alkaline Zinc Plating Intermediates

- Bright Nickel Plating Intermediates

- Silver Plating Intermediates

- Nickel Plating Intermediates

- Zinc Plating Intermediates

- Copper Plating Intermediates

- Tin Plating Intermediates

- Chrome Plating Intermediates

- Alloy Plating Intermediates

- Zincate Zinc Plating Intermediates

- Potassium Chloride Zinc Plating Intermediates

- Hardware Acid Copper Plating Intermediates

- Circuit Board Acid Copper Plating Intermediates

- Acid Tin Plating Intermediates

- Other Plating Intermediates

- Electroplating Additives

- Post-treatment Chemicals

-

Others

-

Electroplating Chemicals

- Alloy Plating Chemicals

- Cobalt Plating Chemicals

- Complexing Agent for PCB Plating

- Copper Plating Chemicals

- Methane Disulfonic Acid And Its Salts

- Methane Trisulfonic Acid And Its Salts

- Nickel Plating Chemicals

- Nickel Salt for Plating

- Selenium Plating Chemicals

- Sulfo Acetic Acid & Its Salts

- Tin Plating Chemicals

- Tin salt for Plating

- Zinc Plating Chemicals

- Other Plating Chemicals

- Electro-plating Solution

- Plating Process

-

Electroplating Chemicals

- Services

- Recommendation

- Base Materials

- Applications

- Resource

- Contact Us

![{[CurrentData.Name]}](https://resource.alfa-chemistry.com/structure/6046-93-1.gif)

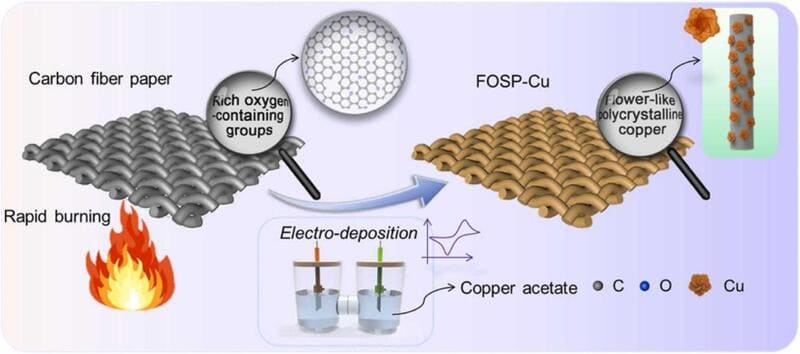

Zhao, Yaling, et al. Nano Energy 97 (2022): 107124.

Zhao, Yaling, et al. Nano Energy 97 (2022): 107124.

Jabeen, Saadia, et al. Applied Nanoscience 11 (2021): 79-90.

Jabeen, Saadia, et al. Applied Nanoscience 11 (2021): 79-90.

Kumar, J. Sharath, et al. New Journal of Chemistry 42.5 (2018): 3574-3581.

Kumar, J. Sharath, et al. New Journal of Chemistry 42.5 (2018): 3574-3581.